Feb 11, 2025

Scroll to explore

As a logistics manager, you’re juggling a million moving parts. From coordinating shipments to tracking inventory, inefficiencies can cost your company big—and cost you sleep. In fact, 93% of supply chain leaders are focused on boosting resilience and efficiency in 2025. If you’re tired of battling outdated systems and rising costs, supply chain applications might just be your saving grace.

The right tools give you better visibility, automation, and control over every step of your supply chain. These applications can oversee all aspects of a business's supply chain operations, managing the entire supply chain from order management to warehouse optimization. Imagine knowing exactly where every shipment is, preventing stockouts before they happen, and scaling operations during peak seasons without breaking a sweat. This guide will break down the top supply chain applications, showing you how they tackle your pain points head-on. Let’s dive in!

What is Supply Chain Management?

Supply chain management (SCM) is the backbone of any successful business operation, encompassing the planning, implementation, and control of supply chain activities to meet customer demands efficiently. At its core, SCM involves the seamless movement and storage of raw materials, work-in-process inventory, and finished goods from their point of origin to the final consumer. This intricate process includes several key activities:

Planning: Developing strategies to balance supply and demand, ensuring that resources are used efficiently.

Procurement: Sourcing and acquiring raw materials and components needed for production.

Manufacturing: Transforming raw materials into finished products through various production processes.

Distribution and Logistics: Managing the transportation and storage of goods to ensure timely delivery to customers.

Inventory Management: Monitoring and controlling stock levels to prevent overstocking or stockouts.

Effective supply chain management is crucial for optimizing operations, reducing costs, and enhancing customer satisfaction. By integrating these diverse activities, businesses can create a resilient and agile supply chain that responds swiftly to market changes and customer needs.

Why Supply Chain Applications Are Critical for Logistics Managers

Enhanced Visibility: Real-time tracking tools improve supply chain visibility, showing you exactly where shipments are at any moment.

Cost Savings: Automating logistics operations and inventory management reduces manual errors and cuts transportation costs.

Scalability: With supply planning tools and predictive analytics, you can easily scale operations during peak seasons.

Improved Collaboration: Applications streamline vendor management and supplier relationships by integrating communication channels.

Leveraging Supply Network Data: Modern supply chain applications leverage data from the supply network to enhance vendor comparisons, improve visibility, and support strategic decision-making.

Resilience: Technology provides adaptive solutions to supply chain disruptions, ensuring seamless operations.

Demand Planning: Forecast market demand accurately to meet customer expectations and optimize inventory control.

Inventory Optimization: Leverage advanced analytics to maintain optimal stock levels, minimize costs, and avoid overstocking or stock shortages.

With these tools in place, logistics managers can focus on driving efficiency without being held back by outdated systems.

Key Types of Supply Chain Management Software

1. Supply Chain Planning Software

Supply chain planning software uses predictive analytics and machine learning to anticipate customer demand and optimize resources.

Forecast Market Demand: Accurately predict future trends using advanced insights and demand planning tools.

Optimize Operations Planning: Streamline planning processes to balance production and inventory management.

Enhance Collaboration: Connect key stakeholders involved in supply chain operations.

2. Transportation Management Systems (TMS)

TMS solutions improve transportation management, reduce costs, and ensure real-time visibility into logistics operations.

Automate Route Optimization: Cut transportation costs with route planning tools.

Track Shipments in Real-Time: Enhance supply chain visibility and prevent shipment delays.

Integrate with Logistics Providers: Streamline order fulfillment and vendor management.

3. Inventory Management Software

Effective inventory management software prevents supply chain bottlenecks and reduces costs.

Improve Inventory Control: Maintain balanced stock levels to prevent overstock or stockouts.

Track Direct Materials: Gain visibility into raw materials and stock keeping units (SKUs).

Optimize Demand Forecasting: Use supply chain data to predict inventory needs and reduce waste.

4. Warehouse Management Systems (WMS)

Integrating a warehouse management system within inventory management solutions can track the storage locations of raw materials and retail goods, improving operational efficiency.

Track Inventory Levels: Gain visibility into warehouse processes and ensure inventory optimization.

Automate Processes: Improve quality control and reduce manual tasks.

Integrate Real-Time Data: Use advanced insights to improve warehouse management operations.

Artificial Intelligence in Supply Chain

Artificial intelligence (AI) is revolutionizing the supply chain industry by enabling companies to harness the power of data for smarter decision-making, increased efficiency, and cost reduction. AI can be applied across various facets of supply chain operations, bringing transformative benefits:

Demand Forecasting: AI-driven demand forecasting tools analyze historical data and market trends to predict future customer demand with high accuracy. This helps businesses plan their inventory and production schedules more effectively.

Inventory Management: AI algorithms optimize inventory levels by predicting stock requirements and identifying patterns in consumption. This reduces the risk of overstocking or stockouts, ensuring a balanced inventory.

Logistics Optimization: AI enhances logistics operations by automating route planning, optimizing delivery schedules, and improving real-time tracking of shipments. This leads to reduced transportation costs and improved delivery times.

AI-powered supply chain management software automates routine tasks such as data entry and reporting, providing real-time visibility into supply chain operations. By leveraging machine learning algorithms and natural language processing, AI helps companies analyze large datasets, identify patterns, and make informed predictions about future demand and potential disruptions. This enables businesses to optimize their supply chain planning and execution, ensuring they can respond swiftly to changes in demand and supply conditions.

Supply Chain Analytics and Visibility

In today’s fast-paced and complex supply chain environment, analytics and visibility are critical for maintaining a competitive edge. Supply chain analytics involves using data and statistical methods to analyze and interpret supply chain data, providing valuable insights into performance and identifying areas for improvement. Supply chain visibility, on the other hand, refers to the ability to track and monitor supply chain operations in real-time, allowing companies to respond quickly to disruptions and changes in demand.

Achieving supply chain analytics and visibility requires the use of advanced tools and technologies, including data analytics software, supply chain management software, and Internet of Things (IoT) sensors. These tools enable companies to gain a deeper understanding of their supply chain operations and make data-driven decisions to enhance efficiency, reduce costs, and improve customer satisfaction.

Key benefits of supply chain analytics and visibility include:

Improved Demand Forecasting and Inventory Management: Accurate demand forecasts and optimized inventory levels help prevent overstocking and stockouts.

Optimized Logistics and Transportation Operations: Enhanced visibility into logistics processes allows for better route planning and reduced transportation costs.

Enhanced Supply Chain Resilience and Risk Management: Real-time monitoring helps identify potential disruptions early, allowing for proactive risk management.

Improved Customer Service and Satisfaction: Timely and accurate information about order status and delivery times enhances customer experience.

Cost Reduction and Profitability: Data-driven insights help identify inefficiencies and areas for cost savings, boosting overall profitability.

In summary, supply chain analytics and visibility are essential for companies to navigate the complexities of modern supply chains and stay competitive in the market. By leveraging these capabilities, businesses can make informed decisions that drive efficiency, resilience, and customer satisfaction.

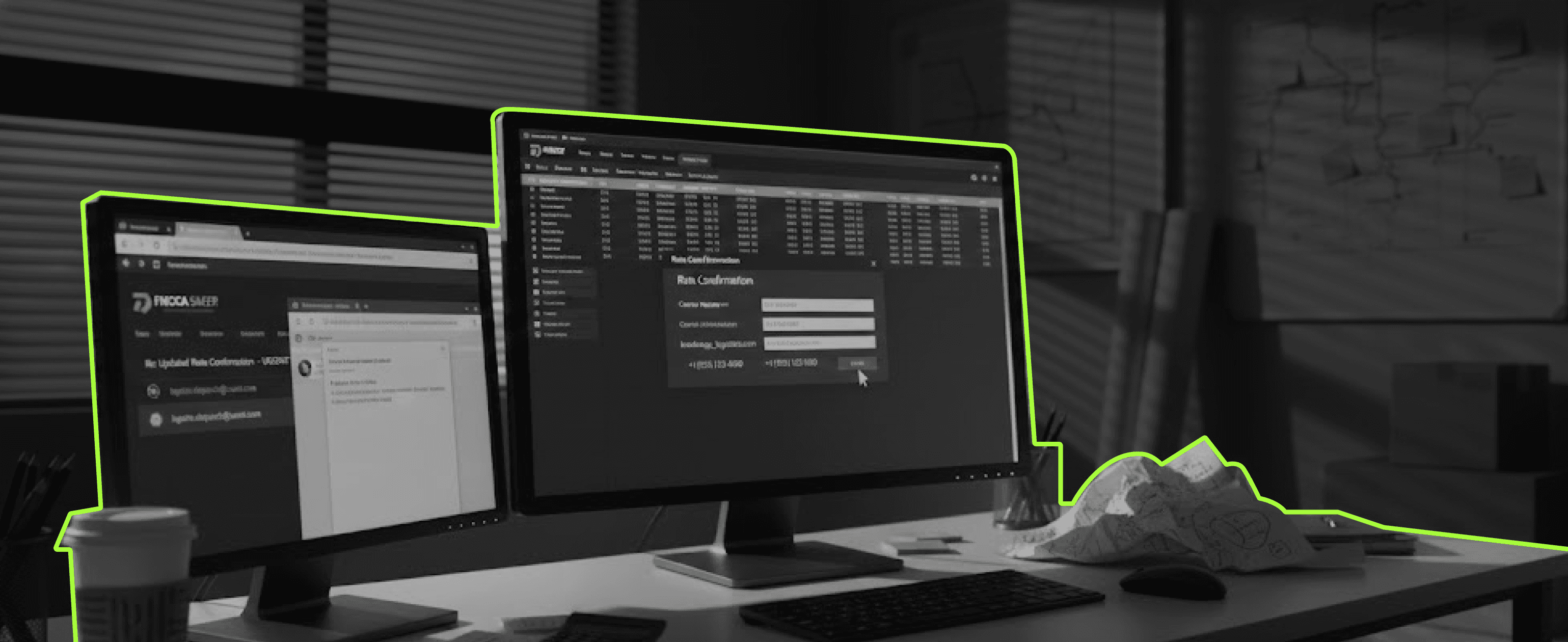

Introducing HaulerHub as a Game-Changing Supply Chain Application

HaulerHub’s Innovative Solution

HaulerHub is a novel and disruptive logistics-based technology platform that redefines how Haulers and Shippers collaborate. Unlike traditional 3PL systems, HaulerHub eliminates intermediaries to directly connect Shippers and Haulers with confidence, speed, and efficiency. This platform is designed to solve the daily challenges logistics managers face, such as high costs, shipment delays, and lack of transparency.

Key Features of HaulerHub

Seamless Connectivity: HaulerHub simplifies freight movement by directly linking Shippers with Haulers, reducing reliance on complex 3PL processes.

Cost Savings: While standard 3PL services charge Haulers 25-30% in service fees, HaulerHub only collects a 10% fee, making it a cost-effective solution for Haulers.

Full Visibility: The platform provides real-time shipment tracking and supply chain visibility, giving logistics managers complete control over their operations.

Scalable Technology: HaulerHub’s AI-driven platform adapts to business needs, ensuring scalability during peak seasons and disruptions.

Customer-Centric Support: HaulerHub offers 24-hour customer service with real people—not bots—to assist users at every step of the logistics journey.

Why Choose HaulerHub?

HaulerHub’s customer-first approach and innovative business model set it apart as a leading supply chain application. By prioritizing transparency, efficiency, and affordability, HaulerHub helps logistics managers reduce costs, improve communication with stakeholders, and streamline their operations.

HaulerHub is more than just software—it’s a transformative tool that empowers logistics managers to control costs, increase efficiency, and meet customer demands with confidence.

How to Choose the Right Supply Chain Application for Your Business

Identify Business Needs: Determine where your supply chain operations face the biggest challenges—from transportation management to inventory control.

Evaluate Features: Look for key features like real-time data, predictive analytics, and integration with enterprise resource planning systems.

Scalability: Choose a solution that can grow with your business during seasonal demand spikes.

Vendor Support: Opt for platforms with reliable customer service and training tools for your teams.

Cost Efficiency: Compare fees and ROI to ensure the solution helps you reduce costs over time.

By carefully assessing these factors, you can select an SCM solution that aligns with your long-term goals and operational needs.

Common Challenges in Implementing Supply Chain Applications

Resistance to Change: Teams may hesitate to adopt new technology without proper training.

Integration Issues: Difficulty integrating new software with existing ERP systems and processes.

High Initial Costs: Some solutions have steep setup fees, requiring careful ROI planning.

Data Security: Protecting sensitive supply chain data from cyber threats.

Scalability Concerns: Ensuring the solution can adapt to growing supply chain networks.

By addressing these challenges proactively, businesses can ensure a smooth transition to new supply chain management software.

The Future of Supply Chain Applications

AI-Driven Insights: Machine learning tools predict demand and reduce costs.

IoT Technology: Real-time tracking enhances transportation management.

Cloud-Based Solutions: Scalable platforms integrate logistics providers and ERP systems.

Advanced Analytics: Use data-driven decisions to improve supply chain resilience and efficiency.

Automation: Streamline order fulfillment, inventory optimization, and production planning.

Conclusion

Supply chain applications are a game-changer for logistics managers aiming to improve efficiency, reduce costs, and streamline operations. By embracing advanced tools like transportation management systems, inventory management software, and AI-driven analytics, you can stay ahead of disruptions, scale operations effortlessly, and meet customer needs.

With platforms like HaulerHub leading the way, you can eliminate traditional supply chain bottlenecks, reduce costs, and create a seamless logistics experience. Invest in the right supply chain management software today to transform your operations and stay competitive in 2025!

FAQ

What is an SCM application?

An SCM (Supply Chain Management) application is software designed to manage, optimize, and automate supply chain processes. It helps businesses track goods, manage inventory, streamline logistics, and collaborate with suppliers and distributors to ensure efficient operations across the entire supply chain.

What is the supply chain app?

A supply chain app is a mobile or web-based tool that facilitates real-time monitoring and management of supply chain activities. It provides features like inventory tracking, shipment updates, supplier collaboration, and demand forecasting, all accessible from a smartphone or desktop. These apps simplify complex supply chain operations for faster decision-making.

What are the four major types of SCM software?

The four main types of SCM software include:

Procurement Software: Manages purchasing processes and supplier relationships.

Inventory Management Software: Optimizes stock levels to prevent overstocking or stockouts.

Logistics and Transportation Software: Focuses on planning and tracking the movement of goods.

Supply Chain Planning Software: Forecasts demand, production needs, and supply chain strategies to improve efficiency.

What is supply chain app?

A supply chain app refers to software applications—usually cloud-based—that enable businesses to monitor and manage supply chain functions in real-time. These apps improve visibility, efficiency, and communication across suppliers, manufacturers, and distributors, ensuring seamless operations.

What is an example of supply chain software?

An example of supply chain software is SAP Integrated Business Planning (IBP). SAP IBP combines demand planning, inventory optimization, and supply chain analytics into one platform, enabling businesses to respond quickly to market changes.

Other examples include:

Oracle Supply Chain Management

Blue Yonder Luminate

Microsoft Dynamics 365 Supply Chain Management

Checkout other blogs

Stay ahead of the supply chain.

Break free from costly and complex systems. Sign up with HaulerHub now and make shipping a breeze.